Top 10 Ways 3D Laser Scanning is Used in Construction

The Rise of 3D Laser Scanning in Modern Construction

3D laser scanning is revolutionizing the construction industry by providing high accuracy, efficiency, and data-driven insights. Incorporating 3D laser scanning into construction projects allows for precise measurements and detailed documentation, reducing the likelihood of costly errors and rework. This technology enhances project timelines by speeding up data collection processes and improving collaboration among stakeholders. Additionally, the comprehensive digital models created through 3D laser scanning enable better visualization of designs, allowing teams to identify potential issues before they arise. As a result, embracing this innovative approach not only streamlines operations but also leads to significant cost savings and enhanced project outcomes in an increasingly competitive industry.

Effectiveness and accuracy are crucial for successfully completing a project in the fast-paced construction industry. With its advanced features, laser scanning technology has become an essential tool for modern building methods. Below are five key ways laser scanning is transforming the construction industry, improving accuracy, and speeding up procedures. Firstly, laser scanning provides precise measurements and detailed 3D models, which significantly reduce errors in the design phase. This accuracy ensures that structures are built exactly to specifications, minimizing costly rework. Secondly, it enables efficient site analysis and documentation. By capturing existing conditions quickly and thoroughly, project teams can make informed decisions earlier in the process. Thirdly, laser scanning facilitates better collaboration among stakeholders.

The technology allows for seamless sharing of data across various platforms, ensuring all parties have access to up-to-date information. Fourthly, it enhances safety by reducing the need for manual site surveys in potentially hazardous environments. With remote data capture capabilities, workers can collect necessary information without physical presence on site. Lastly, laser scanning speeds up construction timelines by streamlining workflows. Rapid data collection and processing mean that projects move from concept to completion faster than traditional methods allow. Incorporating laser scanning technology into your construction projects not only boosts efficiency but also sets a new standard for precision and innovation in the industry.

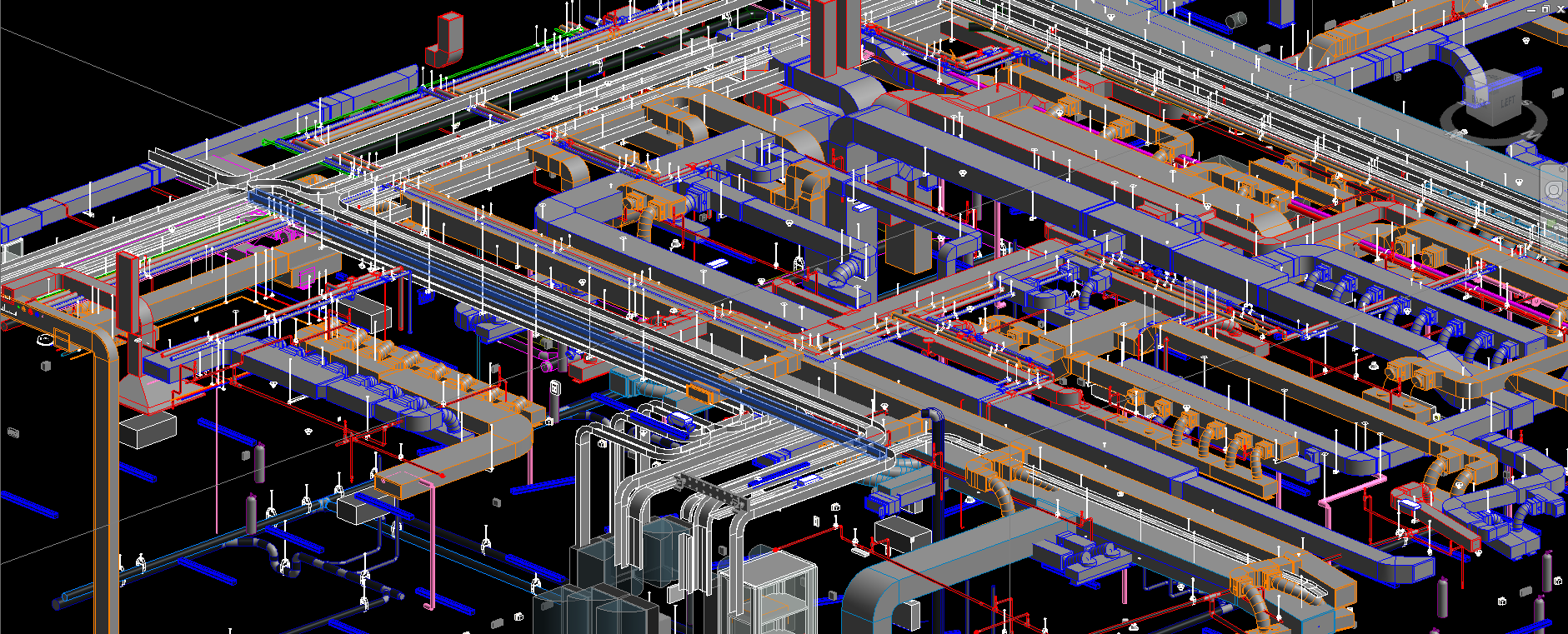

By collecting millions of precise data points from a construction site, laser scanning enables the creation of highly accurate as-built models. A laser scanner generates beams that reflect off objects and return to the device, forming a dense “point cloud” of geographic information. These point clouds are then used to produce detailed 3D models of existing structures. that can greatly enhance project planning and execution. With these 3D models, architects and engineers can visualize the site with unparalleled accuracy, minimizing errors and reducing costly rework. The detailed data captured allows for better coordination among various teams, facilitating smoother integration of future construction phases.

Laser scanning offers significant time savings compared to traditional surveying methods. It captures comprehensive data quickly, enabling faster decision-making and project progression. This technology also improves safety by allowing remote data collection in hazardous or hard-to-reach areas without putting surveyors at risk. Incorporating laser scanning into your construction workflow not only enhances precision but also streamlines processes, ultimately leading to more efficient project completion and cost-effectiveness. By investing in this cutting-edge technology, you are ensuring that your projects stay ahead of the curve in terms of innovation and quality assurance.

Here are the top 10 ways in which this innovative technology is being utilized:

Creating Accurate As-Built Models:

3D laser scanning captures precise dimensions and geometries of a building, allowing for the creation of detailed as-built models. These models serve as a reliable reference throughout the construction process and beyond.

Improving Construction Documentation:

Traditional methods of documentation can be prone to errors and often time-consuming. 3D laser scanning provides comprehensive and precise documentation, ensuring all stakeholders have accurate and consistent data.

Facilitating Clash Detection:

Before physical construction begins, 3D models derived from laser scans can be used to identify potential clashes between different building systems (e.g., mechanical, electrical, and plumbing). Resolving these issues virtually saves time and money.

Enhancing Quality Control:

Laser scanning offers an objective way to assess the quality of work performed. It provides a detailed comparison between the planned models and the constructed building at any stage, allowing for immediate rectification of discrepancies.

Supporting Facility Management:

Post-construction, the data captured through 3D laser scanning can be integrated into Building Information Models (BIM) to aid in the ongoing management and maintenance of the building, optimizing operations and reducing costs.

Streamlining Renovations and Retrofits:

For renovation projects, 3D scans ensure that project teams have a clear understanding of the existing conditions, which helps in planning and designing more effectively.

Accelerating Project Timelines:

By providing accurate data quickly, 3D laser scanning can significantly reduce surveying time, thus accelerating the design and construction phases. This helps in keeping projects on schedule.

Reducing Rework and Waste:

Accurate scans translate into precise construction, reducing the likelihood of costly rework and material waste. This not only saves money but also promotes sustainable construction practices.

Enhancing Safety:

Using laser scans to assess the integrity of structures and identify potential hazards can greatly enhance onsite safety. It reduces the need for physical inspections in potentially dangerous areas.

Improving Communication Among Stakeholders:

3D models and visualizations derived from laser scans can be easily understood by all project stakeholders, regardless of their technical background. This improves communication and collaboration across various teams.

Conclusion

The integration of 3D laser scanning in construction projects represents a significant advancement in building technology. By enabling more accurate, efficient, and effective planning and execution, it not only saves time and costs but also enhances the overall quality of construction projects. As this technology continues to evolve, its adoption will likely become a standard practice, shaping the future of construction in profound ways.