The Importance of Precision in Precast Detailing for Construction Projects

Why Precast Detailing and Precast Design Services by MEP Global Engineering Are Unmatched

Precast concrete construction stands as a pinnacle of modern building techniques, offering a multitude of compelling advantages that streamline the construction process and enhance the overall quality of projects. Its durability and strength are unmatched, providing a long-lasting solution that significantly reduces maintenance costs over time. Additionally, the precision manufacturing process ensures consistent quality and adherence to stringent standards, eliminating many of the common issues associated with traditional construction methods. Furthermore, precast concrete construction allows for faster project completion. The off-site fabrication of components means that work can proceed simultaneously on multiple fronts, reducing on-site labor requirements and minimizing disruptions.

This efficiency translates into substantial cost savings and a quicker return on investment. Moreover, the versatility of precast concrete cannot be overstated. It can be molded into a wide variety of shapes and sizes, accommodating creative architectural designs while maintaining structural integrity. This flexibility makes it an ideal choice for various applications, from residential buildings to large-scale commercial projects. In conclusion, opting for precast concrete is not just a smart choice; it is an essential strategy for any forward-thinking construction endeavor aiming to achieve excellence in both performance and aesthetics.

The durability and longevity of precast concrete ensure that structures built with it require less maintenance and fewer repairs over time, reducing long-term costs significantly. Furthermore, its production process is more environmentally friendly compared to traditional methods, as it allows for better waste management and energy efficiency. By integrating precast concrete into your projects, you are not only adopting a material that enhances the quality of construction but also committing to a sustainable future. It’s clear that in today’s competitive market, choosing materials that offer both superior performance and environmental benefits is non-negotiable. Therefore, embracing precast concrete isn’t merely an option—it’s a critical decision that will set your projects apart in terms of innovation and responsibility. Don’t let outdated methods hold back your potential for growth and excellence. Make the switch to precast concrete today and see firsthand how it can revolutionize your construction processes while delivering unmatched results.

Precast concrete construction is a modern, cost-efficient, and high-quality method that minimizes on-site labor and reduces construction time. It offers many advantages over traditional methods, including architectural efficiency, cost savings, improved quality, aesthetics, and shorter timelines. The precast building construction process can be briefly outlined as follows.

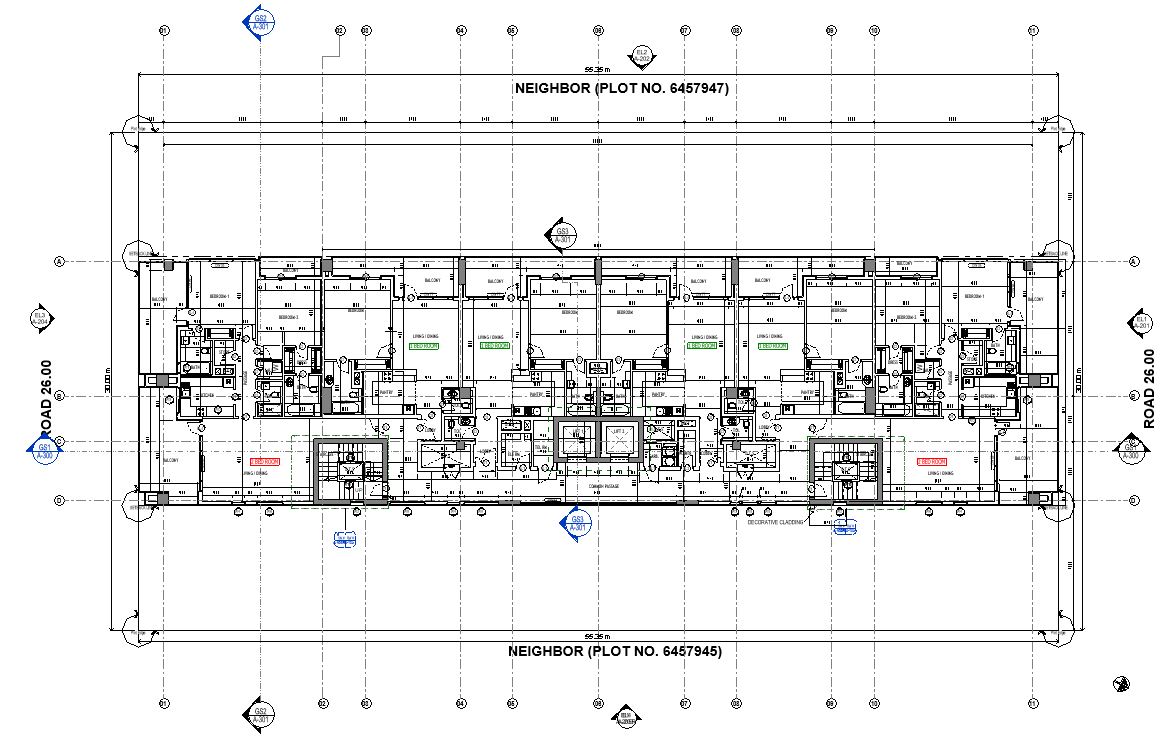

First, the design phase involves creating detailed plans and specifications tailored to the project‘s requirements. Next, the production phase sees these designs brought to life in a controlled factory environment, ensuring precision and consistency. Once the components are manufactured, they are transported to the construction site. At this stage, on-site assembly begins with careful coordination and planning to place each precast element accurately.

This step significantly reduces labor costs and minimizes disruptions compared to traditional methods. Finally, finishing touches such as sealing joints and applying coatings ensure durability and aesthetic appeal. By embracing precast concrete construction, developers can achieve superior results in efficiency, quality control, and overall project timelines—making it a smart choice for modern building projects.

Our Services:

- Concept structural design

- Finalization of precast structural system in consultation with Architect and Contractor.

- Detailed structural design & detailing

- Production of precast elements

- Transportation of precast elements

- Erection of precast elements

- Jointing of precast elements

Concept design

- Working out the suitable precast structural scheme

- Typical floor plans and details

- BOQ estimation

- Detailed structural design

- Optimization of the member sizes

- Design calculation and report

- Precast elements design

- Joint details

- GFC drawings

- Erection drawing

Detailing

- Element shop drawing

- Building information modelling (BIM)

- Bar bending schedule (BBS)

- Quantity calculation

- Shop drawing checking

Precast facility design

- Recommendation for precast mould and machinery

- Layout for factory setup and its structural design

Here’s a closer look at how this innovative method revolutionizes construction:

Efficiency in Production:

Precast concrete components are manufactured in a controlled factory environment, which allows for consistent quality and precision. This controlled setting reduces the likelihood of errors and defects that are often encountered in traditional on-site concrete work, leading to a higher standard of building components.

Reduced Construction Time:

By shifting much of the labor-intensive work from the construction site to a factory, precast concrete significantly cuts down on-site construction time. Elements arrive on-site ready to be assembled, which accelerates the overall building process and allows for quicker project completion, a crucial advantage in time-sensitive projects.

Lower Labor Requirements on Site:

As elements are manufactured off-site, the need for skilled labor on-site is reduced. This not only helps in managing labor costs but also reduces the logistical challenges of coordinating large teams on a construction site. Moreover, it can be a substantial benefit in regions with a scarcity of skilled construction workers.

Cost Efficiency:

While the initial costs of setting up or outsourcing a precast production facility can be significant, the long-term savings are substantial. Reduced construction times lead to lower overall labor costs. Additionally, the efficiency of material use in a factory setting minimizes waste, further driving down costs.

Enhanced Durability and Quality:

Precast concrete structures are known for their robustness and long service life. The factory setting allows for better control over the mixture and curing of the concrete, resulting in products that often exceed the performance specifications of standard cast-in-place concrete. This durability translates into lower maintenance costs over the building’s lifespan.

Flexibility in Design:

Precast concrete is incredibly versatile and can be molded into a wide variety of shapes, sizes, and finishes. This flexibility allows architects and designers to create aesthetic and functional structures that can be both appealing and tailored to specific requirements.

Environmental Benefits:

With reduced site disturbance, less debris, and lower emissions from on-site work, precast concrete is a more environmentally friendly construction method. The ability to recycle materials and use supplementary cementitious materials in the mix further enhances its sustainability profile.

In conclusion, precast concrete construction is not just a method; it’s a strategic approach that aligns with the goals of modern construction—efficiency, quality, and sustainability. By embracing this technique, the construction industry can address many of its contemporary challenges, including labor shortages, time constraints, and environmental impact. It is clear that precast concrete construction will continue to be a critical component of the industry’s evolution.

Benefits of Implementing BIM in Infrastructure Projects

[…] is reflected in the superior quality of your BIM services. This high standard ensures that every project detail is modeled with precision, significantly reducing errors and enhancing the overall project […]

Importance of Adopting BIM for Infrastructure Projects

[…] traditional infrastructure planning by integrating BIM technology to offer a more strategic and detailed analysis of projects. This allows for a comprehensive visualization of the entire project lifecycle, from conception […]

Structural Design Services with Our Expert Team - MEP Global

[…] Previous Post Successful Implementation of MEP BIM Services in Complex Projects Next Post The Importance of Precision in Precast Detailing for Construction […]

The Importance of Effective MEP Design and Coordination

[…] component of any functional structure. Each aspect of MEP requires specialized knowledge and precise execution during construction projects. Engineers must collaborate closely with architects to integrate these systems seamlessly into the […]

Transform Your Projects with Expert Laser Scanning Services

[…] in capturing digital information about physical objects. By using LiDAR, your services offer precise and detailed 3D representations, ensuring that clients receive the highest quality […]

The Evolution of Scan-to-BIM Technology in Utility Mapping

[…] utilities, a complex maze of pipes, cables, and conduits, has always been a major obstacle to construction and infrastructure projects. This often leads to costly delays due to incorrect or incomplete records and dangerous hits on […]

Top 10 Ways 3D Laser Scanning is Used in Construction

[…] and accuracy are crucial for successfully completing a project in the fast-paced construction industry. With its advanced features, laser scanning technology has become an essential tool for […]