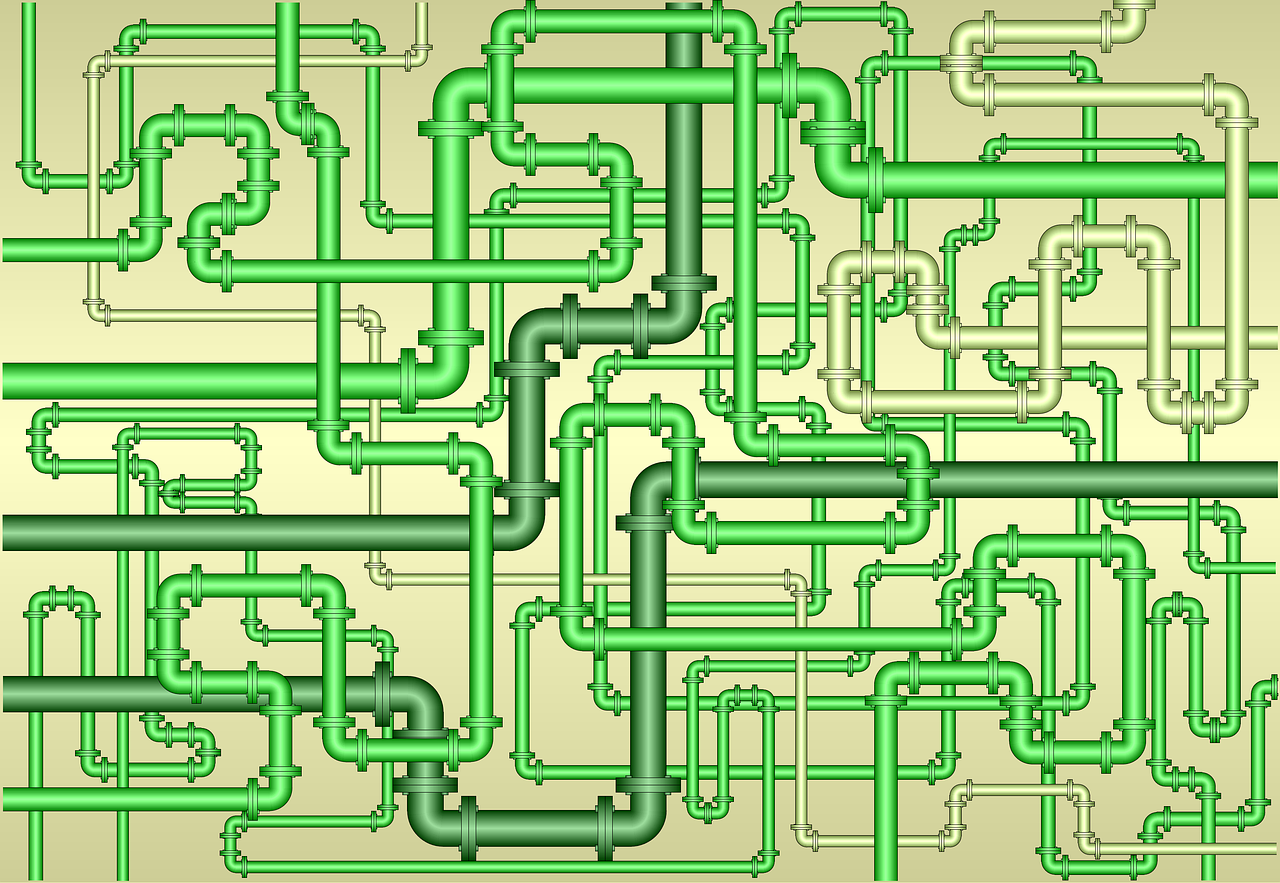

Piping and Instrumentation Diagram/Drawing (P&ID) Services

Piping and Instrumentation Diagram/Drawing (P&ID) Services – Piping & Instrumentation Diagram (P&ID) – P&ID Drafting & Designing

P&ID Drawing Services – MEP Global Engineering India is a premier of piping and instrumentation diagram (P&ID drawings) services provider that is delivered on time, on budget and which embraces the latest AutoCAD technology. A P&ID is a detailed graphical representation of a process including the hardware and software (e.g., piping, equipment, instrumentation) necessary to design, construct and operate the facility.

We provide piping and instrumentation diagram (P&ID drawings) services to those engineers who wishing to outsource their mechanical projects. Piping and instrumentation diagram (P&ID) play a very significant role in the maintenance and modification of the process. Our company serves the clients around the worlds since 2007. Our mechanical engineering teams of young minds and experienced heads have ability to satisfy our client’s P&ID projects needs with expertise in managing mechanical engineering drawings and designs used in a variety of industries.

MEP Global Engineering India basic process for Creating P&ID

* Pipe lines are represented by single lines in P&ID

* Instrumentation signals and connection lines are represented by different types of dashed lines

* Industry standards for the P&ID are ISA S5.1 and ISO 14617-6

* P&ID should be readable either from left to right or from right to left of the drawing

* P&ID is the representation of the process equipment/instruments sequence and not the distances between the equipment’s/instruments

MEP Global Engineering India – Piping and Instrumentation diagram (p&id drawings) includes:

* Instrumentation and designations

* Mechanical equipment with names and numbers

* All valves and their identifications

* Process piping, sizes and identification

* Miscellaneous – vents, drains, special fittings, sampling lines, reducers, increasers and swagers

* Permanent start-up and flush lines

* Flow directions

* Interconnections references

* Control inputs and outputs, interlocks

* Interfaces for class changes

* Seismic category

* Quality level

* Annunciation inputs

* Computer control system input

* Vendor and contractor interfaces

* Identification of components and subsystems delivered by others

* Intended physical sequence of the equipment