MEP Global Engineering Specialized in Point Cloud to BIM MEP Service

Revolutionize Your MEP Global Engineering Projects with Point Cloud to BIM MEP Modeling Services

MEP Global Engineering Point Cloud To BIM Services – Computer software options for prefabrication and MEP Global Engineering – Top MEP Design and BIM Company in building abound. This short article tries to enable establish the right healthy, with regards to the style of prefabrication expected.

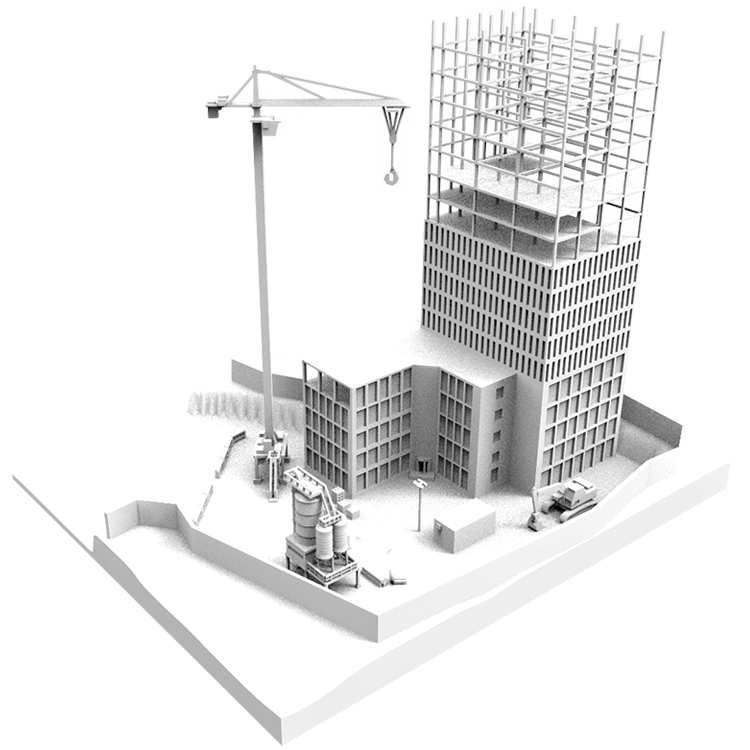

The prefabricated building of parts permits engineering as well as other function to carry on extra rapidly and with much less means on web site since the web site is starting to glimpse a lot more of a location for assembly, making use of things which are pre-fabricated. Prefabricated parts are built using a number of software package that specially allows the generation of MEP (M&E) prefabrication modules and plant skids along with structural and architecturally made properties and making factors. We glance at a few of the different types of prefabrication in building as well as program that allows it, together with BIM (Making Data Modelling) engineering.

Prefabricated development services or Design for Manufacture and Assembly (MEP Global Engineering – Top MEP Design and BIM Company) or modular construction companies as They are really acknowledged, are commonly perceived to apply to accomplish models for traditional use. But modular design includes over that. It includes a wide selection of sub-assemblies and prefabricated aspects, for example fire stairs, elevators, plumbing, heating and cooling and ADA-compliant spaces, that may be produced off web-site and transported to the worksite.

Additional complex aspects of the setting up, for instance a facade with panels, is usually prefabricated. Even subcomponents which can be repeated through a job, for instance affected person rooms in health care amenities, bathrooms, lecture rooms and science labs in instructional institutions, lend by themselves to the process of prefabrication. The numerous array of prefabricated elements can be broadly categorized into 3 sorts: structural, architectural and engineering-related. Each of those MEP Global Engineering – Top MEP Design and BIM Company elements are explored in more depth in this article.

Structural Prefabrication:

The options for MEP Global Engineering – Top MEP Design and BIM Company are Just about countless inside the structural design and style Room. Tall tower blocks or huge halls, wherever even load-bearing partitions, at the same time, as retaining partitions of L form, are elements of a construction which can be prefabricated. Load-bearing partitions are commonly exterior walls of a creating and may even be walls concerning apartments, which bolster the framework’s rigidity and these can now be produced off web-site and delivered to site. Forged in molds for prefabrication are waffle models, put in grid patterns, which might be used for flooring/roofing. Other aspects routinely prefabricated, possibly as complete models or various ingredient parts for assembly on web site, involve:

For buildings that use metal frames, it is possible to fabricate various tales without having pillars, beams and concrete. These steel frames are created and manufactured from Laptop or computer designs specifically linked to CNC (Laptop numerical control) equipment, guaranteeing superior levels of accuracy and velocity of erection.

Suited to residential structures, prefabricated box element engineering includes a process exactly where a framework is assembled with ready-to-assemble box units off site. These kinds of box aspects commonly contain a load-bearing frame, partitions, flooring in addition to a roof, with Home windows, HVAC and electrical gear and fittings.

Architectural Prefabrication:

Obviously, most of the structural aspects crafted will also be considered to be architectural features as well as the detail that is certainly established for a similar involves the architectural layout and making code needs for off-web page manufacture. Prefabrication factors frequently Employed in architecture

Incorporate:

Engineering Prefabrication:

Prefabricated, reinforced and pre-pressured factors of advanced technological and sophisticated structure are Utilized in the engineering factors of assignments far too. Prefabricated elements utilized in engineering involve a number of unique factors, including the assemblies of: A modular procedure skid, or plant skid, is a method inside of a body that is well transported. Particular person skids comprise method devices, and various process skids might be assembled to generate complete moveable plants, in some cases generally known as ‘a process in a very box’. Multi-skid method methods may perhaps consist of coordinated raw supplies skids, utilities skids and processing models. Multiple skids allow parallel design.

A plant area, mechanical space or a boiler home, is usually a space or region inside a structure that is dedicated to mechanical tools and linked electrical tools, all of that may be prefabricated. The plant space usually has the next: Modular ceiling and riser methods encompass constructing parts to retail outlet, method and approach. These programs ensure it is a lot quicker and simpler to assemble the setting up companies Remedy on web site. Prefabricated factors are useful as plant skids, in plant rooms and as ceiling and riser modules simply because they have currently regarded all hanging and attachments to your module and therefore hangars and fitting individual providers on internet site aren’t essential. Commonly, these modules are created in the course of the 3D BIM coordination stage, in which before setting up will allow a more effective format.

Application:

Prefabrication for architecture, composition and MEP (M&E) expert services is useful for an economical and successful prefabrication course of action. A lot of the far more well-liked computer software

Answers utilized include:

AutoCAD, Revit, Inventor, Fabrication The popular software program for prefabrication in development are Revit, AutoCAD and Inventor. They supply: For the duration of design, SDS/two, IDAT Precast and Autodesk Fabrication are applicable software program selections that help the generation of precise structural and MEP 3D styles for prefabrication. Additionally, Autodesk’s Revit computer software functions efficiently Together with the producing functions of Autodesk Inventor to deliver prefabrication modules.

The prefabrication model by Inventor communicates any alterations Together with the architectural design and style and the Computer Numerical Management (CNC) factors. For every form of prefabrication module, one Revit team will determine the discipline element. All discipline styles will need to have aspects in order that modules are geometrically divided. This file can be utilized as a whole module for prefabrication. For each type of prefabrication module within a venture, there exists a single exclusive module model. Any module team/assembly might be updated, altered, replaced or deleted, though Each individual deviation is audited, recognized or denied.

At this stage, a BIM workflow to the drawing and Examination of prefabricated modules may be produced in Revit. It may then observe alterations. That has a file in the modules’ prefabrication parameters, info is usually counted, analysed and translated. With all the parameter values, filters and module-precise views could be established, facilitating coordination in between the different undertaking groups.

In AutoCAD, a schematic drawing of a prefabricated aspect variety and dimension values of the concerned part are displayed. It may then crank out 3D drawings of described elements and aspect parameters are specified.

Autodesk’s Fabrication CADmep™, Fabrication ESTmep™ and Fabrication CAMduct™ application aid element and fabricate better structures. BIM 360 Team, Revit, and Fabrication equipment can talk, view, mark up and assessment undertaking design documents from wherever, and keep connected to the extended design and style group.

SEMA:

With refined information and macro systems, SEMA software package can be adapted to the specific demands of a business. SEMA supports prefabricated design with very simple operations to put features in roofs, ceilings or partitions in a quick and productive way.

SEMA attributes extensive editing features and regular 3D graphic updates to double-Verify the construction. Layouts and drawings with purchaser inputs are swiftly created. Versatile macros are supplied, especially for stairs.

SEMA also supplies 3D visualization from a number of angles. The ‘environment’ of objects, which include walls, Home windows, ceilings or home furniture, is often seen with photorealistic displays, and a variety of practical 3D objects for visualization can be found. Also, 3D objects is usually imported. Gentle and shadow measurements contribute on the Visible actuality of your objects.

The scale of an item in its unfinished state can be used to work out figures, in just a few minutes, for quotations in design. In-depth assembly points, for instance reference points for fixing bracket methods, might be calculated to your millimeter. SEMA delivers substantial libraries of fasteners, brackets, close types, tenons, scarf joints, lamellar connectors, dowels and metal connections with bolts.

Solidworks:

Simple to operate, easily adaptable for rising parts that may be tough to generate, which include curved stairs, Solidworks, part of Dassault Systems, is effective for developing large-close factors. It will increase productiveness, with a variety of information and specialized communication input and offers simulation technological innovation to help you verify patterns. Solidworks automates the purchasing, configuring, developing and developing of prefabricated elements. It features Good Modelling, Movement, Simulation, Toolbox, To Analyst, Circuit Functions, Photo View 360, ScanTo3D, e-drawings and DWG editor. Solid works developed other program solutions to assist 3D CAD, simulation, item facts management, technological communication, electrical style and 3Dexperince. Even the price of a new product can be estimated using the integrated automated manufacturing Price tag instruments, saving time and increasing productivity of designers and engineers.

CATIA:

CATIA, with the DELMIA application, shows consumers how the setting up’s factors might be assembled. Having a 3D model, though all components are represented, the complexity of design will not be apparent. DELMIA details the sequence and strategy of building, piece by piece and in depth.

To summaries and conclude, the increasing utilization of BIM (developing facts modelling) engineering in the development field supports the good results of modular construction. A BIM ecosystem encourages a collaborative procedure, integrating the disciplines of architecture, engineering and design. BIM hyperlinks time and 3D knowledge seamlessly, leading to accurate predictions of schedules involving factory generation to on-website assembly, thus supporting prefabrication.

Automation products basically gets rid of the store drawing section and several manufacturers can manufacture modules for on-web-site assembly. Styles are very detailed and integrated with other sides of output. Clashes are detected in the course of layout, resulting in sizeable personal savings in each time and price. Its style and design stage and coordination phase integration of all aspects helps make prefabricated construction probable. Some of the critical modules of construction companies, including the plant place, h2o pipes, bogs, etcetera., can be fabricated off internet site as Element of the BIM approach. This will save time, given that Significantly from the critical tests, such as pressure exams and air tightness assessments, are concluded inside the manufacturing unit.

This number of tests for every solution implies that the ensuing good quality is in close proximity to ideal and clashes and also other problems are discovered prior to the product or service reaches the internet site. Heating and cooling loads, HVAC duct sizing and pipe sizing is often calculated. Also, considering the fact that modules and elements are created inside the manufacturing unit, the quantity from the workforce on web site is reduced to an awesome extent. In addition, BIM will allow creating companies analyses and assists compute an educated estimate of how the setting up will operate after building. Getting a product ensures that Vitality-saving systems might be integrated into the design early in the procedure. The design will also advise clients on their own proposed bills.

Despite having a preference of convenient computer software alternatives very easily accessible, some companies choose to build their own personal fabrication software package, due to labor shortages, decreased margins, tighter schedules, poor quality Regulate implementation, the result of inclement temperature, elaborate components and basic safety troubles. For numerous development providers, although, the way ahead for prefabrication processes stays making use of the choice of economical software program currently available or getting a companion Along with the expertise and experience to do so.

The architectural structure approach is a posh collaboration concerning architects, designers, drafters, contractors and building teams. Outsourcing a part or the complete layout procedure calls for specific scheduling and effective management. To empower sustainability within just such a world-wide eco-program There’s a need to have for precise scheduling, economical workflow Investigation, integrated venture administration, focused methods with research, contemporary two-way communication strategies, high quality, confidentiality and accountability policies.

Ahead of talking about the top 5 criteria, this short article summarizes the phases in the architectural style and design procedure and types of architectural design and style output and just how they can influence outsourcing decisions.

The Architectural Style and design System and Outsourcing

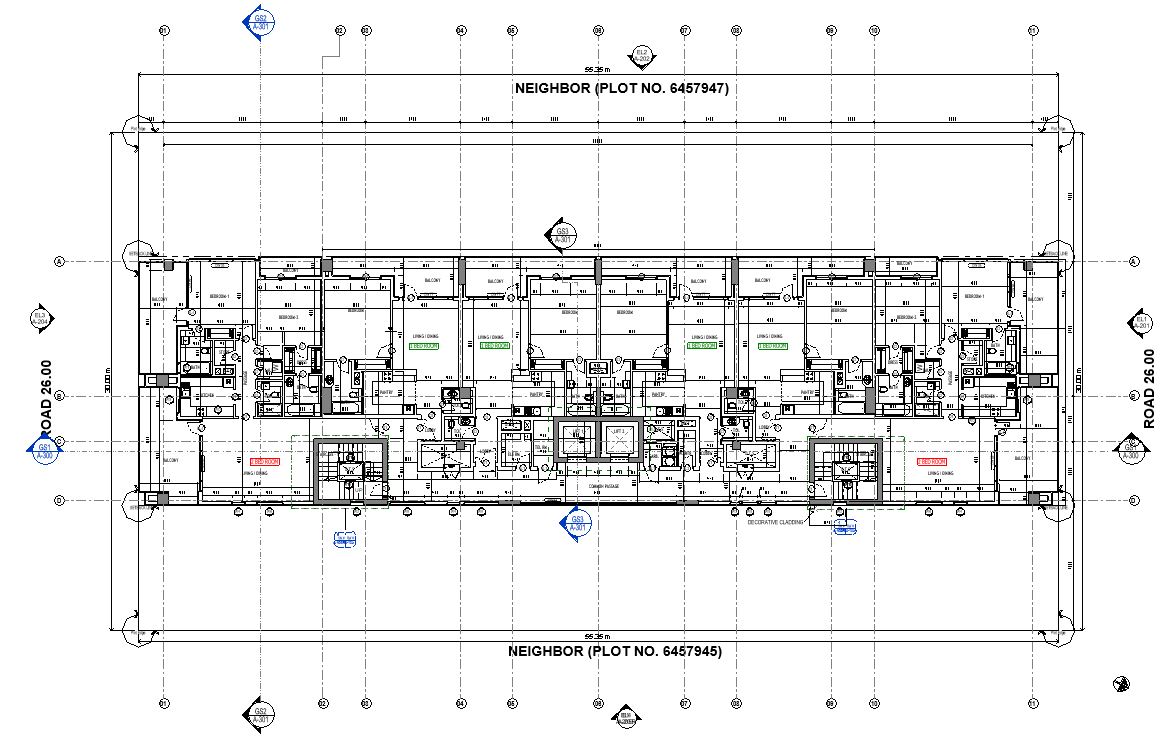

The basic phases associated with the architectural layout method when outsourcing contains generation of schematic layouts, development of design and style according to the choice designed, preparing of development paperwork dependent on last style range (this features planning of drawings, complex specs, 3D products, walkthroughs and blueprints), aiding with the bidding process and monitoring the development course of action for conformance with design and style.

Stage one – Creation of Schematic Styles

With this section, there is a have to have for distinct information for example design and style preferences, finances requirements and most well-liked output. Based upon this details, architectural outsourcing corporations or offshore CAD teams can make correct style and design options in an array of output formats. Architectural style and design outputs could range between 3D CAD models, architectural BIM modelling, interactive walkthroughs or digitally transformed blueprints. Browse more details on architectural style and design outputs talked over further more in the following paragraphs.

Stage 2 – Improvement of Style

Based upon the design option picked out, the Original style and design and price estimates is going to be revised and needed modifications are going to be made. There has to be two-way interaction During this section to finalize the details of the look in advance of continuing to the following section. A lot more firms are beginning to outsource this stage, though communication is required to ensure that the design continues to be intact.

Period 3 – Planning of Building Files

As soon as the final design is agreed upon, the mandatory documents will need to be geared up for development, permits and bidding. According to the look output chosen, models, models or blueprints will be ready to permit contractors to have organized for the following section of bidding. This period is typically the preferred when it comes to outsourcing as it is actually in influence detailing the look and is also labor intensive. The use of Revit in recent years coupled with on the net collaboration resources has enabled offshore outsourcing to get performed with the opportunity to evaluation output and specifications periodically and without interrupting the overall workflow and timescales of the venture.

Phase 4 – Assisting with Bidding and Charges of Portions

Within this period, architectural outsourcing corporations can guide with getting ready packages, furnishing lists of resources and portions and giving Price estimates in advance of bids are sought. Contracting businesses are increasingly using Revit Architecture to generate detailed types and drawings with the previous phases and thus have Considerably of the info from the model presently. The presentation in the bill of material and amount details turns into extra of an issue as the precision of the information is often underpinned by an exact design model and drawings. At the time handed about these facts, it should help to choose a contractor who’s got recognized the design blueprint properly and delivered an accurate bid accordingly.

Period five – Checking the Construction Process & As Created Status Although this stage is typically managed at a local stage, outsourcing organizations is usually included to update the design to replicate the as set up or as created position to make sure a handover for services divisions to handle the internet site.

Usually, structure growth and development doc sets are more than likely to be outsourced to architectural CAD outsourcing services companies. Whichever solution is outsourced, it can be crucial to know the thorough workflow of the architect or designer to identify processes that can be outsourced and people who may possibly need to be carried out in-house.

Types of Architectural Design and style Output to be considered when Outsourcing: Inside the AEC (architecture, engineering and building) business there are actually various needs when it comes to architectural design and style output.

To grasp which Element of the architectural structure system might be outsourced and what should be retained in-residence, it’s important to be aware of the type of design output that may be developed. Here’s a snapshot of a few of the varieties of architectural structure output that is often viewed as for outsourcing by unique customer varieties including architects, stores, homebuilders and inside designers:

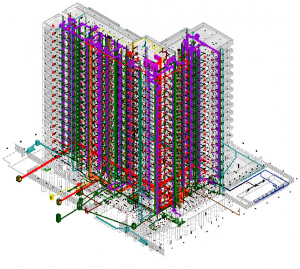

From the AEC marketplace, there is increasing demand to employ BIM-based 3D Digital setting up coupled with conventional second CAD strategies. Outsourcing BIM and CAD processes are extensively regarded as by architectural and building firms to boost in-dwelling efficiency, top quality and effectiveness even though lowering expenditures. Setting up Facts Modelling (BIM) workflow and output for various corporations consists of the subsequent:

o Revit BIM styles are employed to produce in depth strategies, sections and elevations, and precise tools and fixture schedules.

o Development drawing sets are directly developed from BIM designs for each household style.

o Correct schedules and a complete set of drawings needed by building teams are taken in the BIM versions.

o 3D architectural types are established from laser study details. This kind of point cloud BIM types consist of all current developing features, like beams, columns, and inner partitions, amongst Other folks.

o Revit 3D products are developed from place cloud knowledge, for example creating alterations and Architectural Revit Construction solutions and drawings changes from architectural and structural drawings, to Bogus ceiling and extra structural aspects.

o Types are produced through the design advancement, tender and development stages of architectural design assignments.

o Comprehensive construction schedules are developed from clash totally free designs with accurate creating products.

o 3D MEP (M&E) coordinated models with non-BIM apps are established.

o Seamless migration to Revit BIM software package, with specific schedules and production facts.

Top five Criteria for making Outsourcing More Effective

Right after identifying which period from the architectural structure system may be outsourced As well as in what type of structure, it is important to acquire into account the next 5 factors for making outsourcing simpler:

Detect what There exists to achieve from Outsourcing In addition to Charge -In addition to Value, the competencies with the outsourcing husband or wife must be comprehended to recognize how their contribution might help. Whether it’s usage of a hugely skilled useful resource staff, know-how professionals or simplicity of conversation, figuring out essential contributing factors will assure the decision to outsource is successful.

Use Workflow Investigation to Approach exactly and Identify Procedures which might be outsourced -It is important to utilize workflow analysis to map internal procedures, information stream, files shipped and other people accountable for Every approach. Normally, within the architectural layout system, it’s best to retain principle do the job in-property to maintain the integrity of the design. The whole process of detailing the design can be outsourced to leverage the good thing about offshore productiveness at decrease fees by diligent source groups. By workflow Examination and proper setting up it can be done to identify procedures that may be outsourced to boost Main business procedures and productiveness.

Get a Next Opinion – Consider into Consideration Previous Expertise – Exchange data with friends from the field to comprehend their working experience with outsourcing. Learn about the difficulties faced by peers who definitely have outsourced very similar work. Understand how these types of issues is usually tackled and what preparations are required to make it function.

Make an inventory, examine it 2 times – Shortlist Likely Outsourcing Associates – Make an index of prospective outsourcing partners. Get referrals from peers while in the industry. When making a list, look at how nicely the outsourcing companion can meet up with the requirements and deliver a feasible, sustainable, effective and lucrative partnership. Perform a thorough checklist that features quality assurance expectations, software program use, disaster Restoration situations, personnel expertise amounts and cultural fit, before choosing the outsourcing spouse.

Get yourself a Pulse with the Outsourcing Partner Corporation as well as their Ecosystem – To operate by having an outsourcing associate and correctly provide style and design principles one needs to get into one another’s skin. Here’s a checklist to have a much better understanding of the outsourcing associate company and their surroundings.

An excellent Outsourcing Architectural Layout Husband or wife – For making outsourcing more practical, it is vital to take into consideration high quality requirements maintained, technologies applied, project management courses, conversation procedures and processes associated.

An excellent outsourcing architectural style lover will normally have: Have interaction the large ‘O’: In the AEC market, it truly is more and more tricky to satisfy shopper calls for of higher quality requirements and benchmarks, improved Value effectiveness and demanding deadlines on shipping and delivery of projects. Architectural style and design outsourcing has tested that it can provide appreciable benefits to increase effectiveness, efficiency and quality. While the primary force of detailing and delivering types is assigned to a committed and skilled resource crew offshore, in-household teams are offered space to target core functions for instance idea progress.

Specified the complicated eco-technique of collaborating procedures of principle, style and shipping, outsourcing architectural style and design has grown to be a popular preference during the AEC fraternity not just for the benefit of decreasing fees but additionally for strengthening high-quality, efficiency and performance. The achievements of outsourcing come all the way down to deciding upon the best spouse by next the guidelines previously mentioned.

The problem past range involves effective conversation, continual monitoring, continual instruction and ongoing agreement governance to make sure that all functions go on to take advantage of an outsourcing relationship.

HVAC Design Engineering Services | HVAC CAD Services - MEP

[…] can hone your focus towards your strategic core competencies, while rewarding yourself with rich specialized services that guarantee greater returns on your […]

Scan To BIM Modeling Process - MEP Global Engineering-Blog

[…] Point cloud registration: In this step, multiple scans are aligned and merged together to create a unified point cloud. This ensures that the entire space is accurately represented in the model. […]