Key Components of MEP 3D Modeling in Construction Projects

The Critical Importance and Key Components of MEP 3D Modeling in Construction Projects

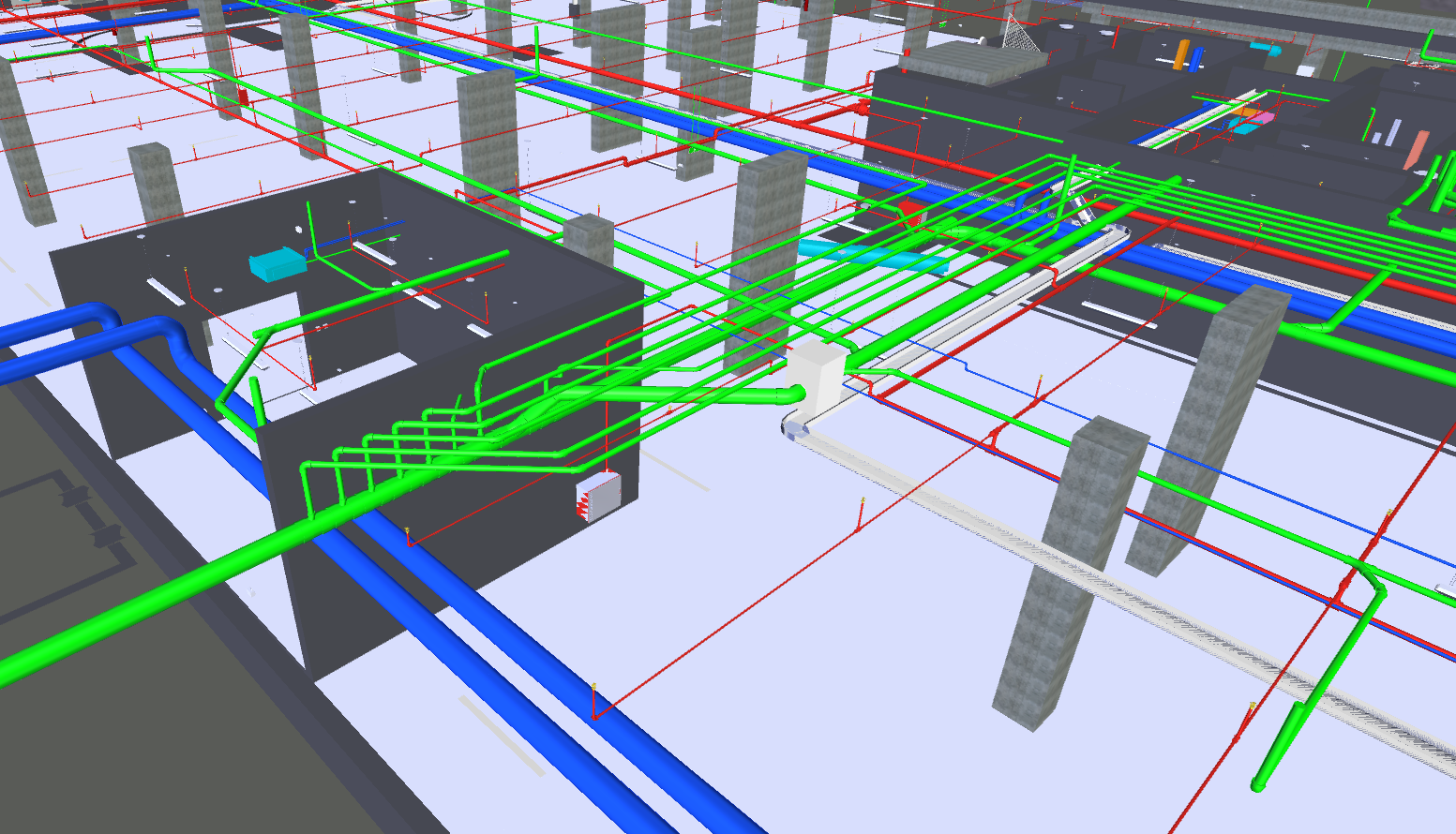

MEP (Mechanical, Electrical, and Plumbing) 3D modeling is critically important for ensuring the success of construction projects. The complexity and integration of MEP systems into buildings demand precision and advanced planning that only 3D modeling can provide. Without the use of 3D modeling, the risk of errors and miscalculations significantly increases, potentially leading to costly delays and safety hazards. By leveraging advanced 3D modeling techniques, we can identify conflicts early in the design phase, optimize system performance, and ensure seamless coordination among various disciplines.

MEP 3D modeling facilitates better communication between stakeholders by providing a clear visual representation of all systems. This transparency not only improves decision-making but also enhances collaboration throughout the project lifecycle. It is imperative that we prioritize and invest in robust MEP 3D modeling practices to maintain our competitive edge and deliver high-quality construction projects on time and within budget.

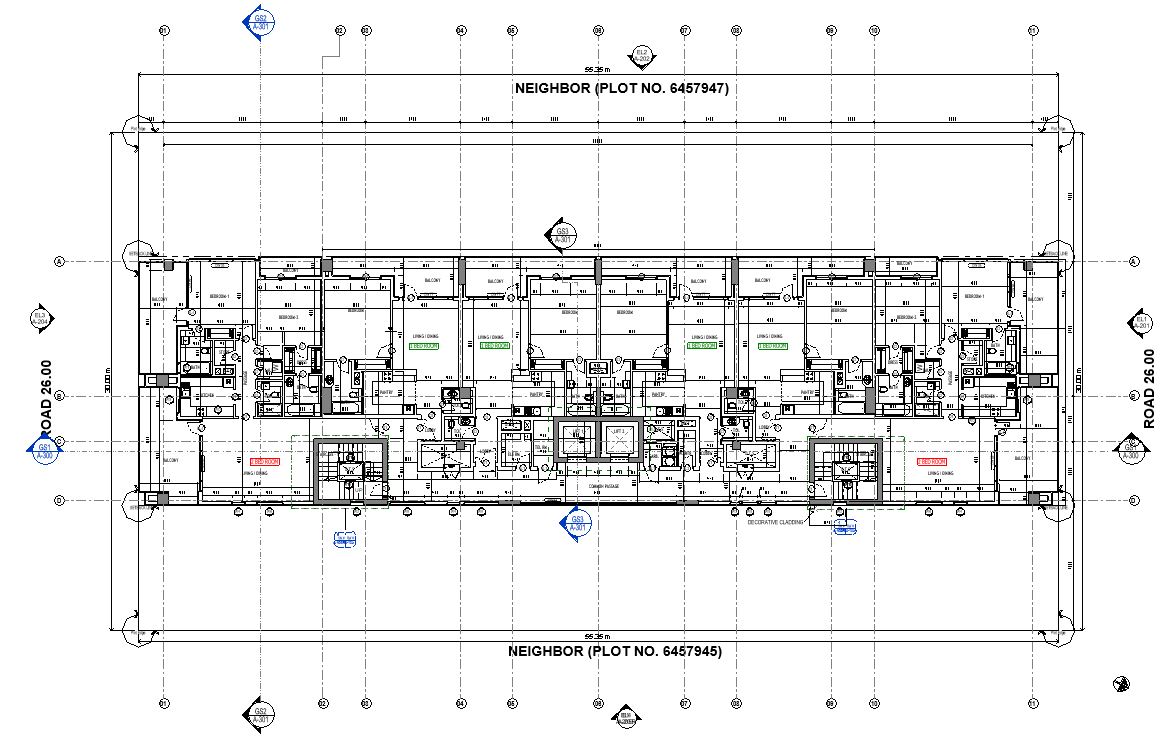

MEP modeling involves creating 3D models of a building’s mechanical, electrical, and plumbing systems. Contractors, engineers, and architects can now see how these systems will work together in the real world thanks to this modern method. Unlike conventional 2D drawings, MEP BIM Modeling Services offer a comprehensive perspective, helping stakeholders spot potential conflicts and resolve them before construction begins.

This proactive approach not only reduces the risk of costly errors and delays but also enhances overall project efficiency. By leveraging MEP BIM Modeling Services, teams can collaborate more effectively, ensuring that every component is correctly integrated within the building’s design. The precision and detail provided by these 3D models facilitate better decision-making and coordination among all parties involved.

MEP modeling allows for simulation of system performance under various conditions, enabling optimization for energy efficiency and sustainability. This modern method is crucial for meeting today’s stringent building standards and regulations. It’s clear that adopting MEP BIM Modeling Services is not just an option but a necessity for any forward-thinking construction project aiming to achieve excellence in both functionality and innovation.

Integrating MEP BIM Modeling Services streamlines collaboration among architects, engineers, and contractors. This cohesive approach minimizes errors and reduces costly rework by ensuring all stakeholders have access to accurate, up-to-date information throughout the project lifecycle. The competitive edge gained through this technology cannot be overstated—projects are completed faster, within budget, and to a higher quality standard. Ignoring the benefits of MEP BIM Modeling Services in today’s rapidly evolving construction industry is not an option.

Companies that fail to embrace these advancements risk falling behind their competitors who are already leveraging this technology to deliver superior results. It is imperative for any organization committed to progressing with innovation and excellence to incorporate these services into their workflow immediately. The time for hesitation has passed; it’s time for decisive action toward a more efficient and sustainable future in construction.

Here’s why MEP 3D modeling is essential and what its key components are:

Importance of MEP 3D Modeling:

Enhanced Coordination and Clash Detection:

MEP 3D modeling facilitates the detection and resolution of clashes between mechanical, electrical, and plumbing systems before construction begins. This proactive approach prevents costly and time-consuming rework, ensuring that all systems fit together within the available space without interference.

Improved Accuracy and Quality:

3D modeling helps in creating detailed and precise representations of MEP systems, which enhances the overall quality of the construction. Accuracy in modeling leads to better installation and functioning of systems, reducing errors and subsequent maintenance issues.

Efficient Project Management:

With MEP 3D modeling, project managers can visualize complex systems in three dimensions, which helps in planning and scheduling the installation more effectively. This visualization supports better decision-making and resource allocation, optimizing the project timeline.

Cost Savings:

Early detection of potential issues and the avoidance of clash during installation significantly reduce unexpected costs associated with changes and delays. Additionally, accurate modeling can optimize material usage and reduce waste.

Enhanced Communication:

MEP 3D models serve as excellent communication tools among various stakeholders, including architects, engineers, contractors, and clients. These models help everyone understand the design and functionality of MEP systems, fostering collaboration and consensus.

Components of MEP 3D Modeling:

Mechanical System Modeling:

This includes the modeling of HVAC systems, ductwork, and other mechanical components. It focuses on optimizing the layout for airflow, system efficiency, and ease of maintenance.

Electrical System Modeling:

This covers the modeling of electrical layouts, including lighting, power systems, fire alarm systems, and control systems. The model integrates these elements within the physical space to ensure accessibility and compliance with safety standards.

Plumbing System Modeling:

Plumbing modeling includes the detailed representation of piping systems, fixtures, and water management systems. It involves the strategic placement of these components to ensure efficient water distribution and waste removal.

Coordination Among Systems:

One of the most critical components of MEP modeling is the coordination between mechanical, electrical, and plumbing systems. This ensures that all systems operate harmoniously within a shared space, without overlaps or conflicts.

Integration with BIM:

MEP 3D modeling is often integrated with Building Information Modeling (BIM) to provide a more comprehensive overview of the entire building project. This integration allows for better performance analysis, lifecycle management, and maintenance planning.

MEP 3D modeling is not just a technical requirement but a strategic asset in construction projects. Its ability to improve design quality, enhance coordination, and streamline project execution makes it indispensable in the modern construction industry. Any construction firm looking to improve project outcomes and operational efficiency should consider investing in advanced MEP 3D modeling capabilities.

Understanding the Basics: Defining BIM and MEP - MEP Global

[…] committed to delivering innovative solutions in a competitive market. Embracing this integration is key to driving progress and achieving excellence in construction […]

Revit Content Creation: The Key to Seamless BIM Integration

[…] and integrate into designs. Suppliers benefit as well, seeing increased demand for their accurately modeled components. It’s imperative for all stakeholders to prioritize the development of robust Revit content. […]

The Advantages of Using BIM in Precast Concrete Design

[…] in the construction process. This not only minimizes costly delays but also enhances overall project quality by ensuring that every component is accurately fabricated and fits seamlessly on site. Moreover, BIM’s ability to simulate […]