Key Advantages of Using Laser Scanning Over Traditional Methods

Maximize Precision with Laser Scanning to Measure Floor Flatness and Levelness

Laser scanning technology has revolutionized the way contractors and inspectors measure the flatness and levelness of concrete floors. The traditional methods, such as using electronic floor profilers, though effective in their time, do not match the precision and efficiency offered by modern laser scanning tools. . These advanced tools provide real-time data with unparalleled accuracy, allowing for immediate adjustments and ensuring the highest quality standards are met. By generating detailed 3D models of the floor surface, laser scanning eliminates guesswork and significantly reduces human error.

Contractors can now identify potential issues before they become costly problems, saving time and resources in the long run. This technology facilitates better communication among project stakeholders by providing clear visual representations that everyone can understand. It is imperative that industry professionals adopt laser scanning technology to stay competitive and deliver superior results in today’s fast-paced construction environment. Ignoring this technological advancement would be a disservice to both clients and contractors alike, as it represents a leap forward in precision engineering and project management efficiency.

Laser scanning provides a far more detailed and accurate assessment, capturing millions of data points across the surface of the floor. This method allows for a comprehensive analysis of the floor’s condition, highlighting even the smallest deviations that could impact the structural integrity or functionality of the floor. By utilizing laser scanning technology, we can identify potential issues that traditional methods might overlook.

This precision is not just a luxury but a necessity for ensuring the longevity and safety of the flooring. It enables us to detect minute imperfections early, preventing costly repairs and downtime in the future. Furthermore, the detailed data collected through laser scanning supports informed decision-making, allowing for targeted interventions rather than broad, inefficient measures. Therefore, adopting laser scanning is not merely an option; it is an imperative step towards maintaining optimal floor performance and safeguarding our investments.

Services

- BIM Services

- MEP BIM

- Architectural BIM

- Structural BIM

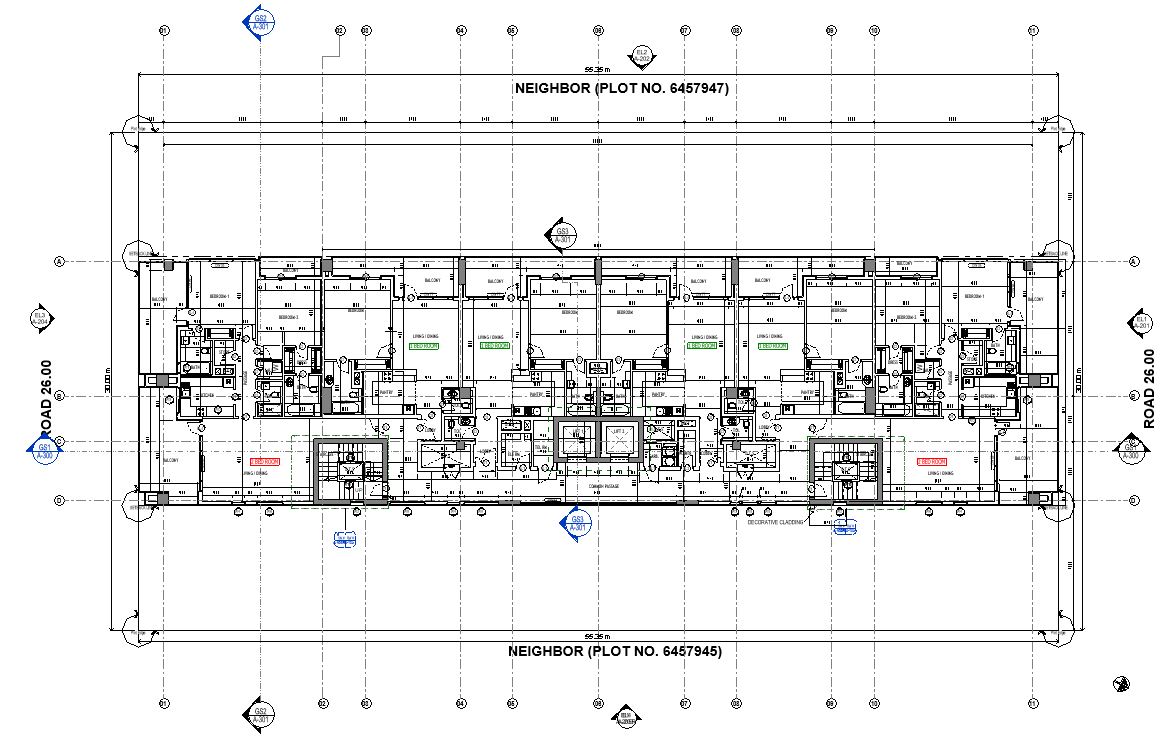

- Scan to BIM

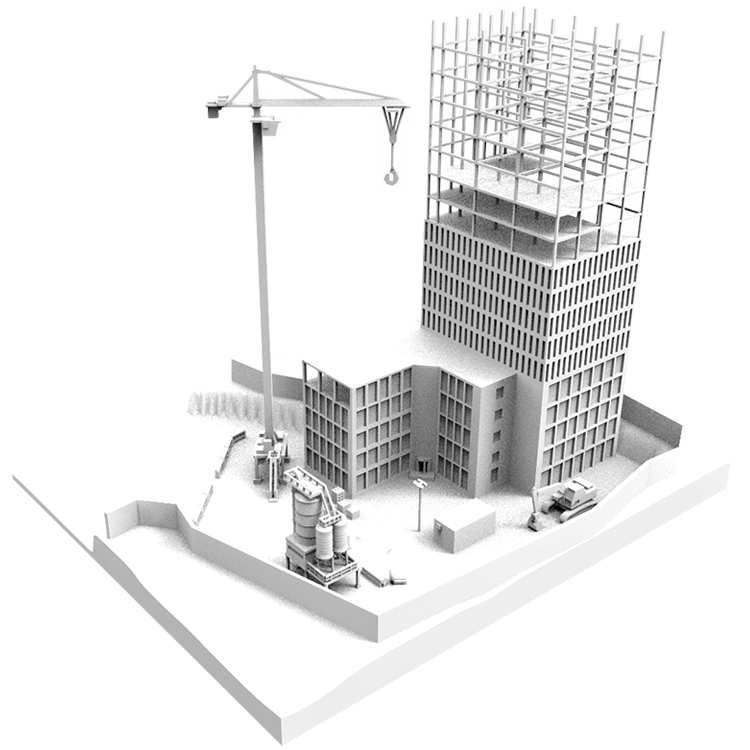

- 4D Scheduling

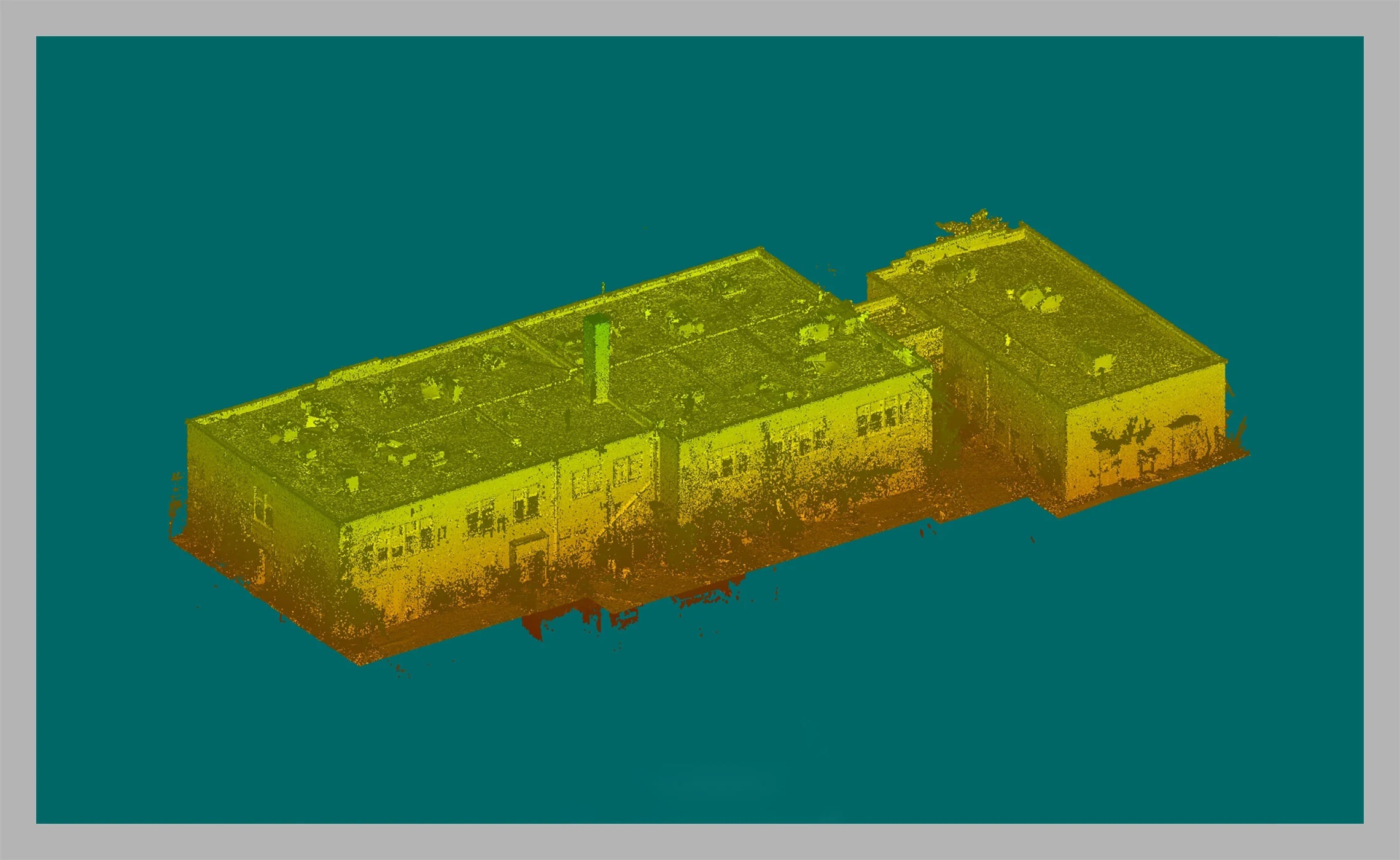

Point cloud data & Scanned images

- Re-design and 2D conversion into 3D models for existing buildings

- Drone technology is used

- 3D surface creation is developed via Point Cloud or any unstructured data points

- MEP and architectural requirements from point cloud data

- Quantity take-off

- BOMS and RFI generation

- Interference checks

- Construction components

- Demolition

- Documentation

- Comparisons

- Planning

- Budget estimates

The Point Cloud modelling services are useful for making parametric 3D BIM and 2D CAD models. They can be used by:

- Property owners

- Land Surveyors

- Laser scanning companies

- Architects

- Engineers (MEP)

- Contractors

- Construction Management companies

The adherence to industry standards such as ASTM (American Society for Testing and Materials), ADA (Americans with Disabilities Act), and AISC (American Institute of Steel Construction) is crucial. Laser scanning tools are designed to comply with these standards, ensuring that all measurements meet the required guidelines and regulations. This compliance is not just about meeting legal requirements—it also ensures safety, accessibility, and durability of the flooring. It is imperative that we prioritize these standards in all our projects. Failure to adhere to ASTM, ADA, and AISC guidelines can result in severe consequences, including legal penalties and compromised safety. By utilizing laser scanning tools that align with these industry standards, we guarantee precise measurements that uphold the integrity of our work.

This diligence directly impacts the overall quality and longevity of our flooring installations. Moreover, compliance with these standards reassures clients of our commitment to excellence and reliability. It is not merely a procedural necessity but a fundamental aspect of delivering superior results. We must continue to invest in advanced technologies such as laser scanning tools to maintain this high level of compliance and ensure every project meets or exceeds industry benchmarks for safety, accessibility, and durability. In conclusion, strict adherence to ASTM, ADA, and AISC standards through the use of compliant laser scanning tools is non-negotiable. This approach safeguards our reputation while fulfilling both regulatory obligations and client expectations for top-tier performance in all flooring projects.

The versatility of laser scanning extends beyond simple measurement. It allows for immediate data processing and integration into digital models using BIM (Building Information Modeling) software. This integration is invaluable in modern construction processes, facilitating better decision-making, enhanced collaboration among stakeholders, and the ability to make real-time adjustments during the construction process.

The precision and accuracy offered by laser scanning cannot be overstated. It minimizes errors that are often costly and time-consuming to correct, thereby streamlining project timelines and budgets. The ability to capture intricate details with high fidelity ensures that every aspect of the construction is meticulously documented and accounted for. Additionally, the use of laser scanning technology drives innovation within the industry. It supports advanced techniques such as prefabrication and modular construction by providing exact specifications that can be replicated off-site with confidence. This not only improves efficiency but also enhances safety by reducing on-site errors. It’s clear that integrating laser scanning into our workflows isn’t just a luxury—it’s a necessity for staying competitive in today’s fast-paced construction environment. Any company aiming to lead in this field must adopt these technologies to meet the growing demands for precision, efficiency, and collaboration in construction projects.

Laser scanning, unlike traditional measurement techniques, collects thorough, incredibly precise as-built data to preserve project tolerances. This scanning technique gathers millions of points across vast sections of concrete, allowing users to swiftly locate and fix high or low spots in flooring. or other structural elements. This level of detail significantly reduces the margin of error, ensuring that any deviations from the original design are promptly identified and rectified. Consequently, laser scanning not only enhances accuracy but also boosts efficiency by minimizing rework and delays. It provides an invaluable digital record that can be revisited for maintenance or future modifications, making it an indispensable tool in modern construction and engineering projects.

In conclusion, the adoption of laser scanning for assessing floor flatness and levelness is a significant advancement in construction technology. It offers unmatched precision, compliance with industry standards, and seamless integration with digital construction methodologies, making it an indispensable tool for modern building projects.

Laser Scan to BIM: The Future of Digital Construction

[…] it significantly reduces the risk of errors that often arise from manual measurements. By utilizing laser scanning, we can obtain exact dimensions down to the millimeter, ensuring that every aspect of the physical […]