BIM Integration in the Structural Steel Detailing Process

BIM Integration in with Structural Steel Detailing Process

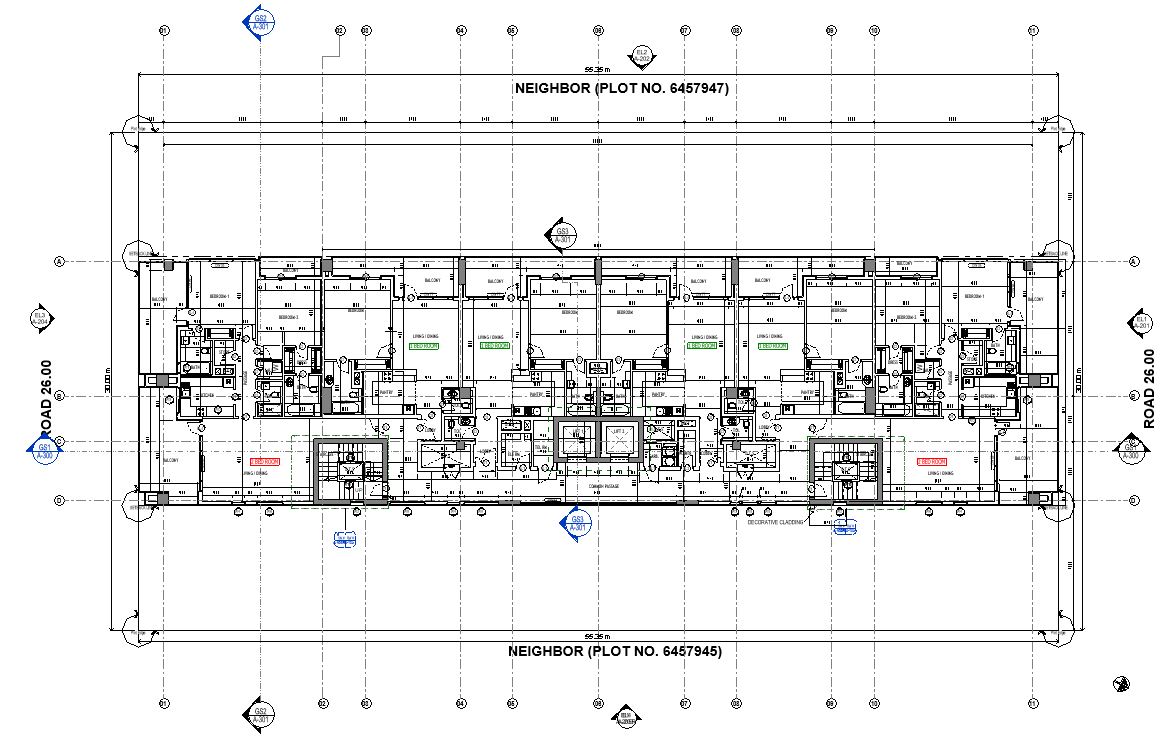

Structural steel detailing is indeed a cornerstone of the construction industry, playing a critical role in both the planning and execution phases of building projects. This meticulous process involves the creation of detailed drawings and plans for steel fabricators and erectors, including specifications for dimensions, materials, and connections. The precision and accuracy provided by structural steel detailing are vital for the stability of the building. Not only does it ensure the integrity of the structure, but it also contributes to cost efficiency and streamlined project timelines. By providing clear and comprehensive instructions, structural steel detailing minimizes errors during fabrication and erection, resulting in fewer delays and reduced material wastage.

As construction projects become increasingly complex, the demand for precise detailing grows ever more critical. Investing in state-of-the-art detailing services can lead to enhanced collaboration across architectural teams and contractors, ultimately delivering superior results that meet or exceed client expectations.

Structural steel detailing services are the strongest pillar of the entire construction industry. The team of structural engineers takes extra care to ensure the project outcome aligns with the latest market trends and required standards and codes. By leveraging advanced technologies and state-of-the-art software, these professionals are able to deliver precise and detailed plans that significantly reduce errors during construction. This attention to detail not only enhances the safety and stability of the structures but also optimizes material usage, leading to cost savings for clients.

Effective structural steel detailing facilitates seamless communication between different teams involved in a project, from architects and contractors to fabricators and erectors. This collaborative approach minimizes delays, streamlines workflows, and ensures that every aspect of the project is executed with precision. Investing in top-notch structural steel detailing services is essential for any construction company striving for excellence. It guarantees a higher level of quality assurance while adhering to stringent timelines, ultimately contributing to successful project completion and client satisfaction.

The age-old method of creating designs and drawings has changed. AEC firms now use the latest technology and processes to succeed in structural steel detailing. Here are some steps that add more value to the project. and enhance efficiency. First, implementing Building Information Modeling (BIM) allows for a more comprehensive understanding of the project, facilitating better collaboration and reducing errors. By creating detailed 3D models, teams can visualize the structure in its entirety and address potential issues before construction begins. Next, utilizing advanced software for automated detailing not only speeds up the process but also ensures precision and consistency across all design elements. These tools are equipped with intelligent features that can adapt to changes swiftly, minimizing downtime.

Integrating cloud-based platforms enhances communication among stakeholders by providing real-time access to project data. This transparency ensures everyone is on the same page and decisions are made based on the most current information. Finally, investing in professional training for team members keeps them abreast of the latest industry standards and technological advancements. Skilled personnel who are familiar with modern tools significantly contribute to maintaining quality and fostering innovation in projects. By adopting these strategies, AEC firms can not only keep up with evolving industry demands but also deliver superior outcomes that exceed client expectations.

Here’s why it holds such importance and how integrating it with Building Information Modeling (BIM) enhances its value.

Benefits of Structural Steel Detailing Services

Accuracy and Precision: Structural steel detailing ensures that every aspect of the steel structure, from beams to columns and connections, is defined with high precision. This accuracy is crucial for the safety and stability of the building, as even minor errors can lead to severe consequences.

Efficiency and Time Savings: Detailed plans help in streamlining the fabrication and assembly processes, reducing the time required for construction. This efficiency not only speeds up project completion but also significantly cuts down on labor and manufacturing costs.

Error Minimization: With advanced software and skilled detailers, potential issues can be identified and resolved during the planning phase, thereby minimizing errors during construction. This proactive approach prevents costly and time-consuming corrections later on.

Enhanced Communication: Detailed drawings facilitate better communication among various contractors and teams involved in the construction process. Everyone has access to the same detailed specifications, which helps in maintaining consistency throughout the project lifecycle.

Compliance and Quality Control: Structural steel detailing helps in ensuring that all construction practices meet the required codes and standards. It also plays a crucial role in quality control, assuring that the materials and workmanship comply with the project specifications and industry norms.

BIM Integration with Structural Steel Detailing Process

Integrating BIM with structural steel detailing brings further enhancements and efficiencies to the construction process:

Improved Collaboration: BIM allows for a multi-dimensional digital representation of the physical and functional characteristics of a project. Integrating BIM with steel detailing facilitates real-time collaboration among architects, engineers, and contractors, which enhances decision-making and reduces rework.

Visualization and Simulation: BIM software enables 3D visualization of the entire structure, including detailed steel components. This capability allows stakeholders to visualize the project outcomes before actual construction begins, enabling adjustments early in the design phase.

Automated Generation of Drawings: BIM tools can automatically generate detailed drawings from the model, reducing manual efforts and the possibility of human errors. This automation speeds up the detailing process and ensures consistency in the drawings produced.

Resource Management: BIM integration helps in effective resource management, predicting material requirements, and scheduling deliveries accordingly. This not only ensures that materials are available when needed but also helps in reducing waste and managing costs.

Enhanced Project Tracking: Through BIM, project stakeholders can track the progress in real-time. Any changes made to the model are automatically updated across all views and documents, keeping everyone informed and ensuring that the project stays on track.

Conclusion

Structural steel detailing is indispensable in the construction industry, offering precision, efficiency, and safety. The integration of BIM with structural steel detailing further elevates its significance by enhancing collaboration, visualization, and project management. As we continue to see advancements in digital construction technologies, the synergy between BIM and structural steel detailing will undoubtedly lead to smarter, faster, and more cost-effective construction practices, aligning with the latest market trends and standards.

Benefits of Integrating BIM Tools in Structural Engineering

[…] Modeling ServicesBIM ServicesMEP BIM Coordination & Clash Detection Services Previous Post BIM Integration in the Structural Steel Detailing Process Next Post AECO Industry: The Role […]