Shop Drawings Benefit Subcontractors in Construction Projects

Shop Drawings: The Ultimate Guide for Subcontractors to Streamline Project Success

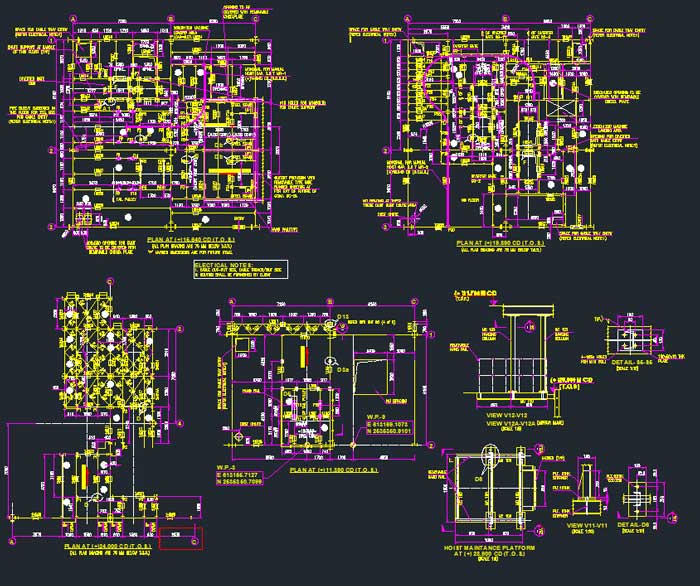

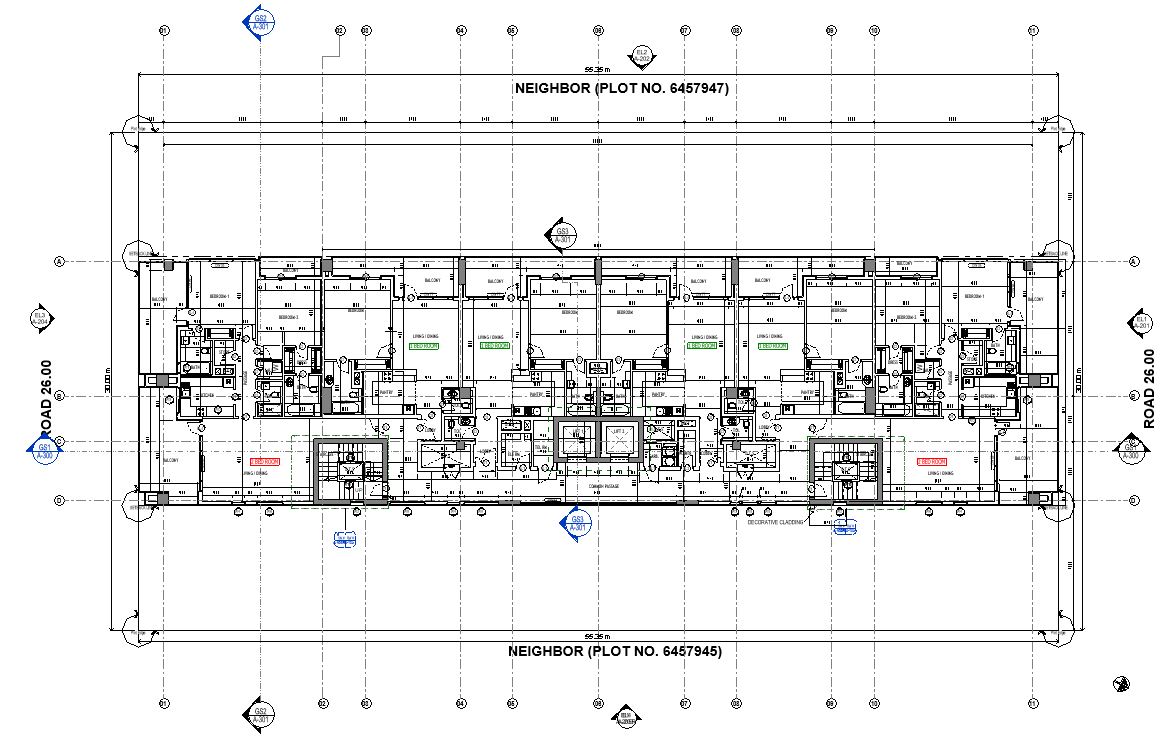

Shop drawings play a pivotal role in the construction industry, particularly for subcontractors who are responsible for the actual fabrication and installation of components. These detailed drawings are crucial as they provide a bridge between design intent and physical construction. Understanding the nuances of shop drawings is essential for ensuring precision in building projects. Let’s delve into the essential guide that highlights the importance, preparation, and review process of shop drawings. to appreciate their indispensable value in successful construction execution. Firstly, shop drawings serve as the detailed visual representations that translate architectural and engineering designs into actionable blueprints for fabrication.

They include critical information such as dimensions, materials, and installation instructions, ensuring that subcontractors have a clear understanding of what is required. This precision minimizes errors during construction, leading to enhanced efficiency and cost savings. The preparation of shop drawings involves meticulous planning and collaboration between designers, engineers, and subcontractors. It is crucial for all parties to engage in open communication to address any discrepancies or potential challenges early on. This collaborative approach not only guarantees accuracy but also fosters a proactive problem-solving environment.

Once prepared, the review process of shop drawings acts as an essential quality control measure. Architects and engineers must meticulously examine these documents to verify compliance with design specifications and regulatory standards. A thorough review ensures that all project stakeholders are aligned on expectations before construction begins. In conclusion, by investing time in the careful preparation and review of shop drawings, construction teams can significantly enhance project outcomes through improved accuracy and reduced risk of costly rework. Emphasizing their importance facilitates smoother operations across all phases of a building project while reinforcing best practices within the industry.

To ensure every component is manufactured, assembled, and installed according to industry standards, fabrication companies rely on shop drawings. These designs include modular elements like elevators and steel beams. Shop drawings are more detailed than engineering and building drawings, indicating the prefabrication process. This article will cover in-depth information about shop drawings as a subcontractor guide, their features, when they should be generated, and the review process. . By understanding the intricacies of shop drawings, subcontractors can significantly enhance the efficiency and accuracy of their projects.

These detailed documents serve as blueprints for production, offering precise measurements and specifications that prevent costly mistakes during construction.

One primary feature of shop drawings is their focus on every minute detail required for accurate fabrication. Unlike standard architectural plans, these drawings provide a comprehensive view that includes dimensions, materials, finishes, and installation methods specific to each component. This level of specificity ensures that all parts fit together seamlessly during assembly. Shop drawings should be generated early in the project timeline to allow sufficient time for review and approval by architects or engineers. This proactive approach helps identify potential issues before they escalate into major problems on the construction site.

The review process is critical in maintaining quality control and ensuring compliance with design intent. During this phase, architects or engineers meticulously examine the shop drawings to confirm that they align with overall project requirements while adhering to safety standards. By leveraging well-prepared shop drawings as a guide throughout the construction process, subcontractors can deliver superior results while minimizing delays and rework—ultimately leading to successful project completions within budget constraints.

Shop Drawings and the Features that Distinguish Them

Shop drawings are detailed, preparatory drawings made by subcontractors or fabricators. They outline how specific elements within a project will be manufactured and installed. Unlike architectural drawings, shop drawings focus on particular components, showing dimensions, manufacturing conventions, and installation details.

Key features of shop drawings include:

– Detail and Precision: They provide precise details about the measurements and specifications of materials, which are crucial for correct fabrication and installation.

– Customization: Tailored to specific construction and fabrication needs, reflecting actual site conditions.

– Integration: Show how individual parts fit within the broader system and interface with other components.

Preparation of Shop Drawings

The preparation of shop drawings is a meticulous process, requiring a deep understanding of both the design intent and the practical aspects of construction.

Steps involved in the preparation include:

Review of Design Drawings: Start by thoroughly reviewing the construction drawings and specifications provided by the design team.

Material Selection: Choose appropriate materials that comply with the specifications and are suitable for the project environment.

Detailing: Create detailed drawings that include all necessary information for fabrication and installation, such as dimensions, procedures, and special instructions.

Software Utilization: Use advanced CAD software and BIM tools to enhance the accuracy and efficiency of the drawings.

Review Process of Shop Drawings

Once shop drawings are prepared, they go through a rigorous review process to ensure they meet all specifications and are aligned with the overall project design.

The review process typically involves:

– Internal Review: Conducted by senior technicians or project managers within the subcontracting firm to ensure all aspects of the drawings are correct and complete.

– Client Submission: The drawings are then submitted to the project’s primary contractor or the design team for approval.

– Feedback and Revisions: Incorporate any feedback or required changes from the design team and resubmit the drawings for final approval.

What is the Need for Shop Drawings?

Shop drawings are indispensable for several reasons:

– Accuracy: They ensure that components are manufactured and installed with precision, fitting seamlessly into the intended design.

– Efficiency: Well-prepared shop drawings reduce the time and resources spent on rework and adjustments during construction.

– Communication: Serve as a clear communication tool among designers, fabricators, and installers, ensuring that everyone has a detailed understanding of what is required.

– Legal and Compliance: Provide documentation that can be useful for meeting regulatory compliance and in case of disputes.

Conclusion

For subcontractors, mastering the art of creating and managing shop drawings is crucial. These drawings not only ensure that components are made and installed correctly but also uphold the integrity and efficiency of the construction process. By providing a detailed guide on how to prepare and review shop drawings, subcontractors can significantly enhance their contributions to construction projects, ensuring successful outcomes and client satisfaction. Shop drawings, therefore, are not just a requirement but a cornerstone of modern construction practices, bridging the gap between design and execution.