The Advantages of Using BIM in Precast Concrete Design

Unlocking the Future of Construction: BIM Integrated Precast Concrete Design for Structural Engineering Projects

Building Information Modeling (BIM) technology has revolutionized the construction industry, offering enhanced visualization, improved coordination, and increased efficiency in building processes. When integrated with precast concrete design, BIM facilitates a seamless and collaborative approach to structural engineering projects. By adopting BIM in precast concrete design, teams can anticipate and address potential issues early in the project lifecycle, reducing costly errors and rework. The ability to visualize complex structures in a digital environment allows for precise planning and coordination among architects, engineers, and contractors. This not only leads to faster project completion but also ensures higher-quality outcomes.

BIM’s data-rich models enhance communication across all stakeholders. With real-time updates and shared access to critical information, decision-making becomes more informed and efficient. As a result, projects benefit from optimized resource allocation and minimized waste. Investing in BIM technology is an investment in the future of construction—a future where innovation drives sustainability and profitability. Adopting this approach will undoubtedly give any company a competitive edge by streamlining operations while delivering superior results to clients.

Compared to traditional construction methods, precast construction is a fast, cost-effective technique offering enhanced quality, speed, and cost advantages. Since the same company usually handles detailed design, prefabrication, and construction, Building Information Modeling (BIM) effectively enhances precast construction processes. by streamlining communication and coordination among all project stakeholders. The integration of BIM in precast construction enables precise planning and visualization, reducing the likelihood of design errors and costly rework. Moreover, BIM provides a comprehensive digital representation of the project, allowing for better resource management and scheduling.

Precast components are manufactured in controlled factory environments, ensuring superior quality control compared to on-site construction. This results in durable structures with consistent finishes. Additionally, the speed at which precast elements can be assembled significantly shortens construction timelines, allowing projects to be completed faster without compromising on quality. From a financial perspective, adopting precast methods reduces labor costs as fewer workers are needed on-site for assembly. It minimizes material wastage since components are produced with precision manufacturing techniques. Ultimately, by combining these benefits—enhanced quality assurance through prefabrication facilities and improved coordination via BIM—precast construction emerges as an exceptionally efficient approach that meets modern demands for both performance and cost-effectiveness in building projects.

Here’s a comprehensive look at how BIM is transforming precast concrete construction:

BIM-Enabled Precast Concrete Construction

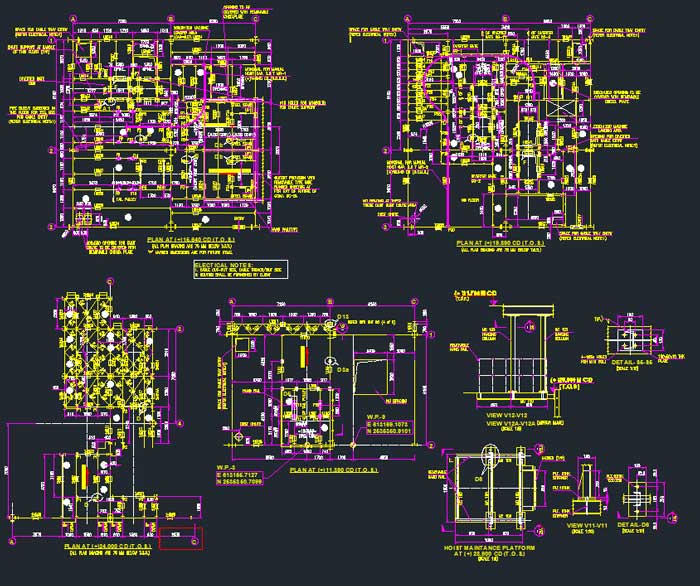

BIM technology in precast concrete construction involves creating digital representations of physical and functional characteristics of places. These BIM models are used to analyze and control the construction process, leading to a more organized, predictable, and efficient workflow. . By leveraging BIM technology, project teams can significantly reduce errors and rework, as the comprehensive models allow for precise planning and coordination among all stakeholders involved in the construction process. This not only minimizes costly delays but also enhances overall project quality by ensuring that every component is accurately fabricated and fits seamlessly on site. Moreover, BIM’s ability to simulate various scenarios enables teams to optimize resources and materials usage, ultimately leading to cost savings.

The technology facilitates better communication between architects, engineers, contractors, and clients by providing a clear visual representation of the project from inception to completion. Additionally, integrating BIM into precast concrete construction supports sustainable building practices by allowing for detailed analysis of environmental impacts throughout the project’s lifecycle. This foresight empowers decision-makers to implement eco-friendly strategies effectively. In summary, adopting BIM technology in precast concrete construction offers numerous advantages that enhance efficiency while fostering collaboration and sustainability in modern building projects.

BIM-Integrated Workflow for Precast Concrete Design

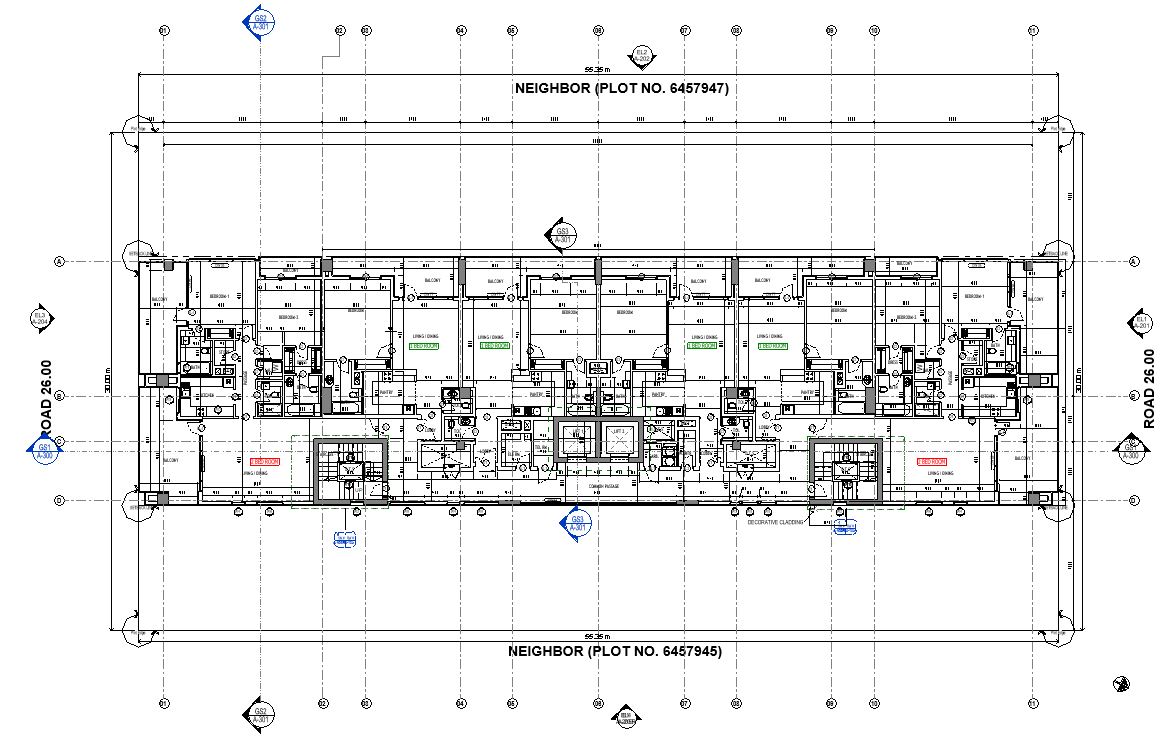

Design and Detailing: Starting with precise digital 3D models, BIM facilitates detailed precast component design including reinforcements, embeds, and connection details, which are crucial for the structural integrity.

Fabrication: BIM models integrate seamlessly with manufacturing processes, allowing for automated machine instructions that lead to high-precision fabrication of precast elements.

Logistics and Installation: BIM helps in planning and visualizing the sequence of installation, managing logistics by tracking the production, delivery, and storage of precast elements.

Assembly and Post-Installation: The use of BIM models continues on-site to guide the precise assembly of precast components, ensuring that everything fits as designed with minimal adjustments needed.

Benefits of Using BIM-Integrated Workflow for Precast Concrete Construction

– Enhanced Accuracy: Reduces errors during the design and construction phases through precise, computer-generated modeling and detailing.

– Improved Coordination: Facilitates better coordination among architects, engineers, and contractors, reducing conflicts and rework.

– Efficiency in Fabrication and Installation: Streamlines the process, from fabrication to installation, optimizing the entire timeline of the project.

– Cost-Effectiveness: Minimizes wastage of materials and time, ultimately leading to cost savings.

– Higher Quality: Ensures that designs adhere to industry standards and regulations, improving the overall quality of the construction.

Precast Concrete Design Challenges Associated with Implementing a BIM-Integrated Workflow

– Software Proficiency: Requires a high level of proficiency in BIM software tools, which may necessitate comprehensive training and investment in new technology.

– Initial Setup Costs: The initial setup cost for integrating BIM into precast concrete design can be significant, although it pays off in the long run.

– Data Management: Managing the vast amount of data generated and ensuring its accuracy can be challenging.

– Integration with Legacy Systems: Integrating BIM with existing systems and workflows in organizations that have previously used traditional methods can pose initial hurdles.

Summing Up

The integration of BIM in precast concrete design represents a significant advancement in the field of structural engineering. Despite the challenges associated with its implementation, the numerous benefits it offers make it an indispensable tool in modern construction. Projects become more manageable, less prone to error, and more cost-effective, leading to better outcomes and higher satisfaction levels among stakeholders. As the construction industry continues to evolve, BIM’s role in enhancing precast concrete construction will undoubtedly grow, further cementing its status as a transformative technology in the field.